The cross-section of a cable wire should be selected to match the current consumption of the connected loads. This article will tell you how to calculate wire size and cross section. An online wire size calculator helps you with dimensioning following your data input.

General information about the cable wire size

Electrical voltage is the separation of electric charges and the current flow due to the directed movement of electrons between two points. This electron movement always causes heat. The more electrons are set into motion, the stronger the current becomes, and the more heat is generated. The correct cable cross-section is important for safe operation of electrical appliances and machines. The electrical wire size is crucial in this respect.

The line for a bell has a smaller cross section than the connecting line of a lathe. The management of a CHP plant, however, is stronger than that of the lathe. If we were to operate the CHP via the line of the lathe or bell, cable fire would occur due to the excessive heat.

The cross section refers to the area of each wire of a cable and its size depends on several factors. On the one hand, there are the electrical data of the connected machine, and structural conditions such as cable length and installation type on the other. We want to explain how these factors affect the cross section and how to calculate a wire cross section. In addition, we provide a wire size calculator.

Function of the cross section

Each line has a resistance, even if it is very small. Every resistance means heat generation and this heat is converted electrical energy. Simply put, we could call this wasted heat a “loss” because it is not used for its intended purpose. This effect is easy to observe with older light bulbs: just a few seconds after switching on, the glass is too hot to touch.

The wire must enable the flow of current with the least possible resistance. In general, the following applies: As the cable cross-section increases, the resistance decreases. This is especially true with very strong heat. With the enlargement of the cross-section, this heat is counteracted. This reduces the risk of excessive heating and prevents fires.

Relationship between temperature and resistance

Due to chemical processes in the material, the electrical resistance of a cable increases with the temperature. That is why we measure a resistance close to 0 with a cold bulb. When switched on, a very strong current is generated, which levels off due to the heating within a fraction of a second. That is why incandescent bulbs usually burn with a big bang when they are switched on and not during operation.

A smaller diameter wire heats up faster at the same current. The heating increases the resistance of the wire, which in turn results in its heating up even faster. This circle prevents some systems from failing for some time after being turned on because heating the line raises resistance.

Wire size calculation formulas

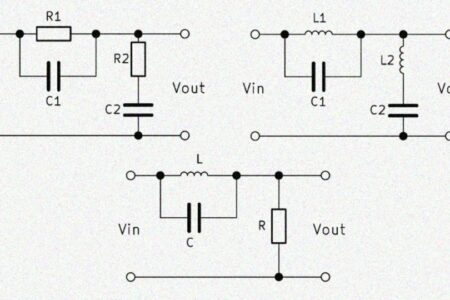

DC calculation of line cross section:

$$ A = \frac{2 \cdot l \cdot I}{\gamma \cdot U_a} $$

Single-phase AC wire calculation:

$$ A = \frac{2 \cdot l \cdot I \cdot \cos \varphi}{\gamma \cdot U_a} $$

Three-phase AC (three-phase current) line cross-section formula:

$$ A = \frac{\sqrt{3} \cdot l \cdot I \cdot \cos \varphi}{\gamma \cdot U_a} $$

The formulas for the cable cross-section look quite complicated at first glance. Therefore, in the next few sections, we will explain how these sizes are arrived at. The values simply have to be entered in the wire size calculator.

Explanation of the components

$l$ = length of the line in meters

$I$ = rated current in amps

$\sqrt{3}$ = chaining factor of three-phase current

$\cos \varphi$ = electrical efficiency of the system

$\gamma$ = conductivity of the line material in Siemens/meters

$U_a$ = Permissible voltage drop of the cable in %

Derivation of the required values

Nominal current $\mathbf{I}$ and efficiency $\mathbf{\cos \varphi}$ can be found in the manual or on the type plate of the machine. Alternatively, the current can be calculated using the known power and voltage. For DC installations, no $\cos \varphi$ is given. This is 1.0 and can be omitted in the calculation.

The length of the line $\mathbf{l}$ is measured exactly along the course of the line and given in meters. For DC and single-phase AC, the length times two is calculated because the current over + and – or L and N flows back and forth.

The linking factor of three-phase current $\mathbf{\sqrt{3}}$ is a fixed value. It arises from the interaction of the three phases, because the current does not just flow back and forth here. This value always remains the same.

The conductivity $\mathbf{\gamma}$ depends on the material used and is 58 for copper. Silver has the highest conductivity at 62, while the older aluminum leads at 37 are significantly lower. In general, the higher the conductivity of the material, the lower its electrical resistance.

The permissible voltage drop $\mathbf{U_a}$ denotes the proportion of the input voltage, which may fall over the line maximum. This maximum voltage drop is generally set at 3% in Germany, unless the installation has special provisions.

Wire size calculator tool

The online calculator helps you to determine the wire size for the desired parameters.

Wire size calculation – Selection of the appropriate line

When calculating the cross section according to the above formula, the result is a value in square millimeters $mm^2$. This will rarely fit exactly on a commercial cross-section. Therefore, the next largest line is always used. If the calculation yields $3.6 \ mm^2$, the next larger cable is laid with $4 \ mm^2$.

In borderline cases, it may also be useful to switch to the next larger cross-section. This would be the case, for example, if the calculation is $3.98 \ mm^2$. In the sense of a reserve, the next size should be used here. A larger cross section has only benefits electrically speaking. The only disadvantages are the slightly higher cost and a larger footprint.

Calculation of wire size – other factors

The permissible current-carrying capacity is also dependent on the ambient temperature. Cable loads may vary at different temperatures. High temperatures are of paramount importance, because they reduce the load capacity. Low temperatures increase the ampacity.

The routing mode of the cable limits the current depending on the materials surrounding the cable. Types of installation A1 to E exist. They depend on whether the cable is laid on the wall, in the wall or freely. As a rule, the calculated conductor cross-section will be far below the limit based on the laying type.

If there is more than one cable, the ampacity must also be adjusted. This is due to the fact that several tightly packed cables can no longer radiate their heat unhindered. There are factors depending on the number of heaped cables by which the current carrying capacity is lowered.

Calculating wire size for several consumers

It is more complicated to calculate a conductor cross section when multiple loads are connected. In principle, all currents could be added together and the length of the common line section is measured. A large cross-section can be calculated based on this. In most cases, however, this line would be significantly oversized, because not all consumers usually receive electricity at the same time. Here, a simultaneity factor is generally expected. There is no clear way to determine it.